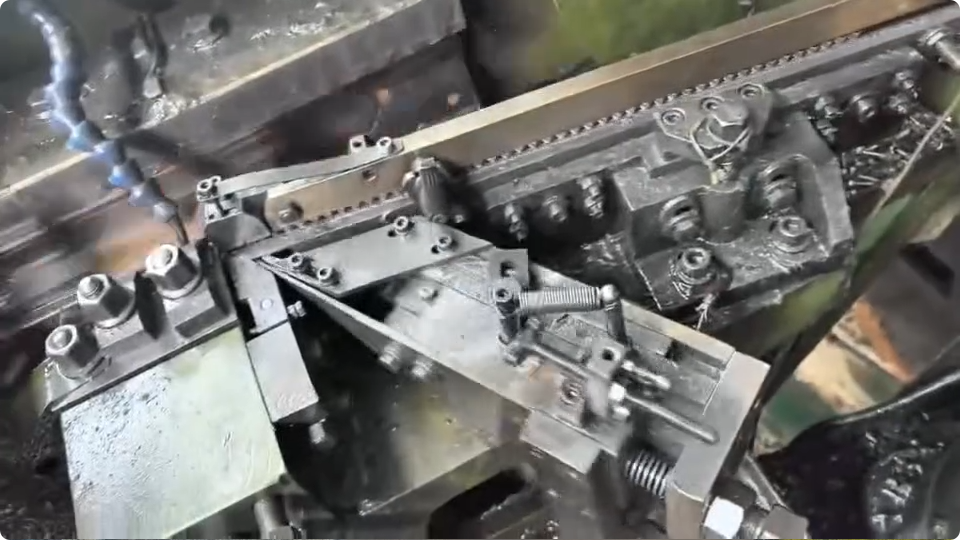

EsteCabeçalho frio de alta velocidadeé uma máquina de encabeçamento frio com duas estações de trabalho, usada principalmente para produzir fixadores simples, como parafusos, rebites e pinos. Este equipamento realiza a conformação em dois estágios em um ciclo de alta velocidade, permitindo uma produção eficiente e contínua. O princípio de funcionamento do cabeçote frio de duas estações é moldar blanks de metal na forma necessária por meio de sucessivas ações de puncionamento, oferecendo qualidade estável e maior produtividade para a fabricação de fixadores padrão.

| Modelo | YTB-0524 |

| Diâmetro em branco (mm) | 0.6-3.5 |

| Comprimento em branco máximo (mm) | 24 |

| Curso (mm) | 38 |

| Espaços em branco por minuto | 170-260 |

| Diâmetro da matriz (mm) | 20 |

| Cof-off morre diâmetro (milímetros) | 13.5 |

| Matriz de punção (1ª) (mm) | 18 |

| Matriz de punção (2ª) (mm) | 18 |

| Motor do corpo | 1HP |

| Motor da bomba de óleo | 1/4HP |

| Total Dimenslon L*W*H (milímetro) | 1250*800*930 |

| Peso aproximado (quilograma) | 850 |

Primeiro, uma rápida atualização: umcabeçalho frio de alta velocidadeA máquina forma peças de metal - como parafusos, parafusos e fixadores - em velocidades notáveis, moldando fios ou hastes de metal a frio, sem aquecimento. Este processo de conformação a frio resulta em alta precisão, excelente utilização do material e propriedades mecânicas superiores em comparação com a usinagem ou forjamento a quente.

Ao avaliar o custo decabeçalho frio de alta velocidademáquinas, considere estes componentes principais:

O preço da etiqueta varia muito com base na capacidade da máquina, nível de automação e personalização. Os modelos básicos podem começar na faixa mais baixa, enquanto os cabeçalhos multi-estação totalmente automatizados com controles avançados podem exigir um prêmio.

As ferramentas são essenciais e muitas vezes um custo recorrente significativo. As matrizes se desgastam ou precisam de ajustes, especialmente com produção de alto volume ou materiais mais resistentes.

Os custos operacionais incluem:

A manutenção regular prolonga a vida útil e o desempenho da máquina. O tempo de inatividade não planejado pode ser caro, afetando os cronogramas de produção e os compromissos do cliente.

O ROI é a sua bússola para avaliar se a máquina de cabeçalho frio vale o investimento. Geralmente é expresso como uma porcentagem e leva em consideração todos os custos versus ganhos em um período definido.

ROI (%) = (Lucro Líquido do Investimento / Custo Total do Investimento) × 100

Para obter uma imagem precisa, considere estas variáveis:

Investir em umcabeçalho frio de alta velocidadeA máquina é um movimento estratégico que pode transformar sua eficiência de fabricação, reduzir custos e melhorar a qualidade do produto. Embora o custo inicial possa parecer significativo, uma análise cuidadosa de custos e cálculos realistas de ROI geralmente revelam benefícios financeiros atraentes. Ao entender todos os componentes de custo e como eles se relacionam com os benefícios da produção, você pode selecionar com confiança uma máquina que atenda às suas necessidades operacionais e metas financeiras.